Al Kennickell Finds Profits Where Others Fear to Go

By Al Kennickell

[stag_dropcap font_size=”100px” style=”normal”]A[/stag_dropcap]s a graduate of The Citadel, the military college of South Carolina, I learned the value of working harder and longer than anyone else. Playing football there under legendary coaches like Bobby Ross, Ralph Friedgen, and Frank Beamer (all former NCAA coaches of the year), I learned that when I thought I had pushed beyond my limits, I still had more to give.There’s a name for things in life that require this level of effort: game-changers. In football, a game-changing play shifts the momentum in a way that fundamentally changes the outcome of the contest. In business, a game-changing “play” fundamentally sets you apart from your competition or creates a new area of profitability.

At The Kennickell Group, where I’m the third-generation owner, we know game-changers because we have evolved our company by finding and committing to them. We offer many of the same services that other printers do — offset and digital printing, wide-format, online storefronts, data analytics, mailing, and fulfillment — but we don’t simply reach for the low-hanging fruit. We go “all in” on more difficult (but ultimately more profitable) lines of business.

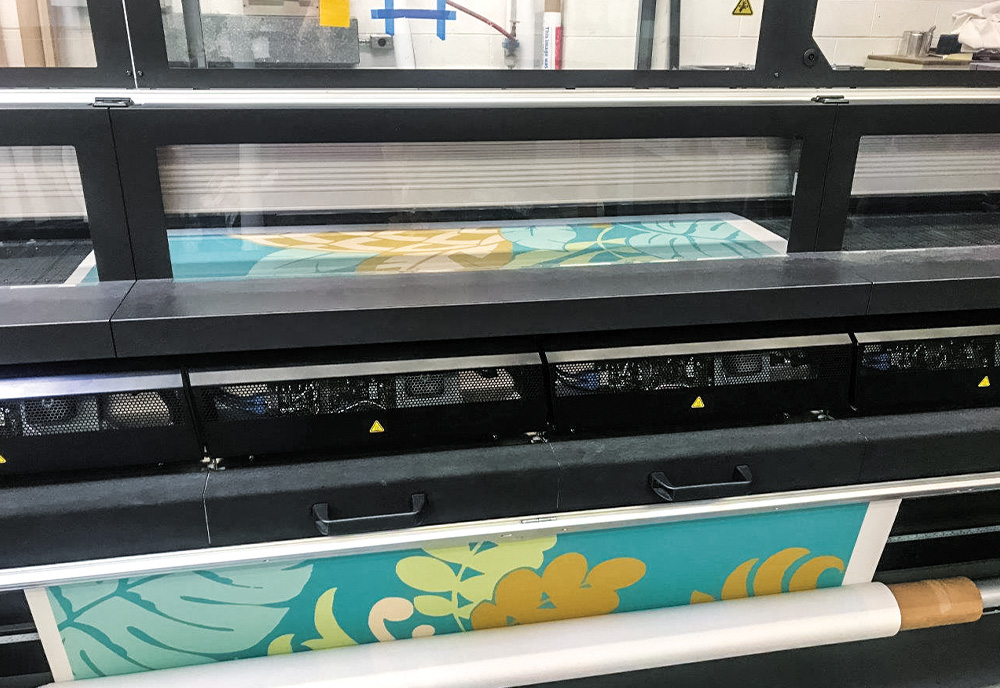

In our wide-format business, for example, in addition to signs and banners, we print on outdoor fabrics and upholstery like umbrellas and branded awnings. Decorative elements are normally sewn onto these products, not printed, to minimize fading. But I didn’t want to do it like everyone else. After months of R&D, we figured out how to print on these materials while still offering the same fade-resistance. Now we can print more complex designs faster and more economically than other shops. And because other companies aren’t willing to put in this same level of effort, we don’t have competition. I don’t know anyone else who’s doing it.

That’s what Kennickell does. We go where others won’t. And what we achieve are new lines of revenue and a reputation for innovation that give us a huge competitive advantage. We dominate the Savannah, GA, market, and our growth continues at a steady annual rate of 10 percent. Our wide-format business alone was up 25 percent in 2018.

Finding a Better Way

Six years ago, we launched one of the most challenging initiatives we’ve undertaken so far: partnering with printers around the globe to print and distribute jobs internationally. Today, we can say that this service is responsible for 25 percent of our overall revenue. Setting up the right international partnerships is extremely challenging. The fact that we do it, and do it well, sets us apart from everyone else.

All of this started because we had one client that needed print brochures for a trade show in Johannesburg, South Africa. They needed more than a dozen versions of a short-run brochure on a very tight turnaround. They had to be delivered on the fifteenth of the month, and the client promised us the files by the fifth — but, as often happens, the files didn’t come in on time.

Ultimately, we pulled off the project, but it was challenging with the logistical and shipping constraints inherent in international distribution. Then, the client wanted us to do it again. This time, to Berlin. Then again, to São Paulo. Every time, it was a scramble. I thought, “There has to be a better way.”

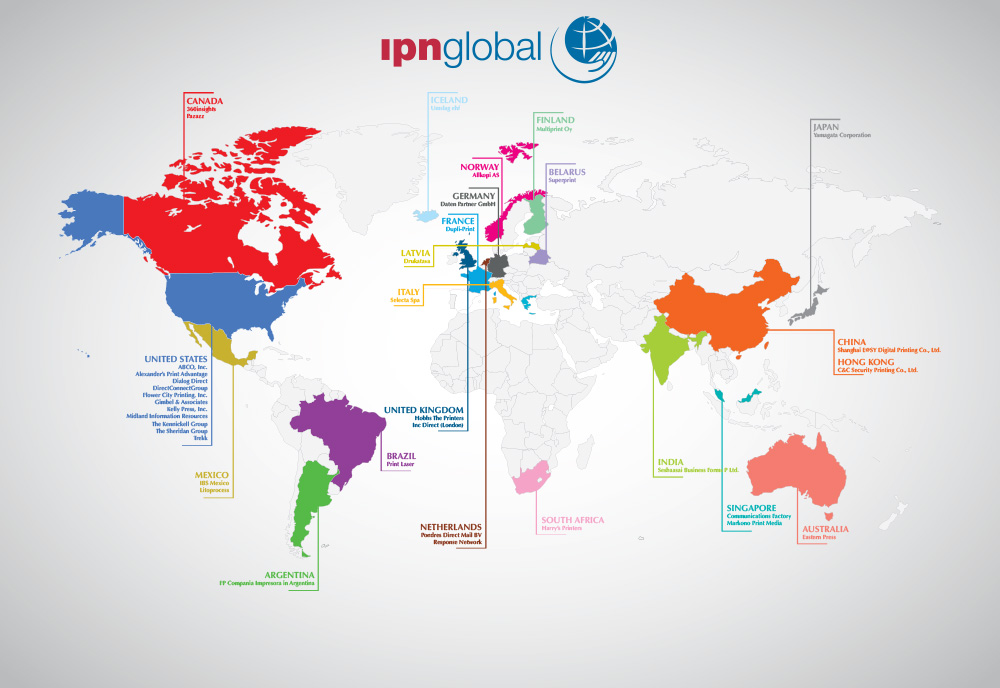

I poked around and discovered an organization called the International Printers Network (IPN Global), an international peer group of printers that partner to use one another’s services to print and deliver files around the world.

I recognized that if we could be a part of the network, the benefits to our clients would be huge. If a U.S. client needs printing in China, it takes 24 hours just to fly there, let alone print, ship, and get the material through customs. By having a partner in China print and deliver the job instead, the shipping would be a fraction of the cost. We could even get it there the same day if necessary. Even if we didn’t have a partner in the destination country, our closest partner in the region could still get it there faster than I could. Just as importantly, local or even regional partners would know the regulations and best practices in their markets and neighboring ones. This would greatly minimize risks and the potential for delays. All of this added up to the potential for huge cost savings and reduced headaches for our clients.

Joining IPN Global would be a game-changer for us. Not just because of the benefits to my clients, but because it offered significant barriers to entry that would deter most of my competition. Membership with IPN requires:

- Finding a sponsor before you can even request to join.

- Being voted in by existing members.

- Committing to a rigorous travel schedule for mandatory group meetings around the world.

- Adhering to detailed business, ethics, and production requirements.

- Giving regular presentations on the things your company is learning and doing.

- Doing it all in person. (Since the network is designed to facilitate business relationships, the decision-maker for the company — in this case, me — must be the one participating in all of these activities. The responsibilities cannot be delegated.)

I looked at these requirements and thought, “This is a huge commitment. Most of my competitors would never do it. I’m in!”

Making It Happen

In 2013, I contacted my local IPN representative in the U.S., who sponsored me to attend the next IPN meeting, held in Barcelona. At this meeting, I made a presentation wherein I provided details of my business, including our business model, competitive environment, equipment and workflow, and quality standards.

“I looked at these requirements and thought, “This is a huge commitment. Most of my competitors would never do it. I’m in!”

Once I made the presentation, the members voted, and I was approved. The next step for me was to begin the process of identifying which of the other 200+ IPN members it made the most sense for me to consider and approach for partnership.

Whenever you’re working with any kind of partner, the number one requirement is trust. This is all the more important when working internationally because I have partners whose production floors I may never see. IPN monitors and enforces business integrity, but it’s still important to find people you relate to and with whom you, personally, feel comfortable.

Because membership requires that you attend at least two of the international meetings every year, I found the best way to find the right partners was at the meetings themselves. Members give presentations at these events, and the topics range from new technologies or services the companies are investigating to business transformations they are navigating. Just by listening, I could quickly identify the smartest guys in the room. Those were the ones with whom I wanted to do business.

In addition to personal chemistry, I was also looking for printers with similar equipment to ours. We wanted partners that would produce results that looked like they came out of our shop. Ultimately, I was able to identify such partners in Western and Eastern Europe, South Africa, Australia, South America, Mexico, Central America, and Asia. That said, since market conditions are always changing and evolving, finding partners with the right match of equipment and capabilities is an ongoing process.

It took two years and six meetings before I identified the members who were the best fit for our quality, format, and run-length requirements. At that point, we started sending test files to each other.

Daring to be Different

I’ve been part of this network for six years. I love that only a handful of printers in the U.S. can do this, yet there are thousands of companies who need it. The competitive advantage can’t be overstated.

Anyone can ship print jobs overseas, but few printers can tap into an entire network of fully vetted printers with whom they have developed business relationships and established trust. Tell me where in the world you want to have brochures delivered, and I have a partner who can get them there — on time, cost-effectively, and with the quality you expect. Very few printers offer that.

“Only a handful of printers in the U.S. can do this, yet there are thousands of companies who need it. The competitive advantage can’t be overstated.”

It’s been a lot of work to get here. Participating in IPN meetings has taken me overseas 25 times in the past six or seven years. The members are my friends now, and we work hard for each other. We don’t want to let one another down. For example, one time I needed a job printed in Amsterdam — a large job that required offset equipment my partner there didn’t have. Still, he said he’d handle it. That’s it. He said nothing about how difficult it would be, who he would outsource it to, or other details of the challenge. He just said, “I’ll take care of it” — and he did. The results were great. Now I know that he’ll adeptly handle whatever I send his way.

Reaping the Rewards

Many of our international jobs come from U.S. companies that have dealerships (such as golf carts or earth-moving equipment) or sales offices around the world. These companies need to send collateral material to many different dealers in different locations, and we have found that automation is the key to maximizing profitability. We set up an online portal for each client that houses its templates for common jobs, such as brochures, data sheets, and spec sheets. The dealers simply log in, place their orders, and then, based on their country, the job is automatically routed to the closest printer.

If the dealer is in the United States or Canada, the job comes to us. If the dealer is overseas, the job goes to the closest IPN partner and is printed and shipped from there.

My clients pay a premium, but that premium is generally offset by greatly reduced freight costs. Even if jobs do require some freight, the cost is much lower than it would be if the job had been printed and shipped from here. I might have to pay $5,000 to ship from the U.S. into an Asian country, for example, but a partner in Singapore can ship it for a few hundred dollars. And, the job can be delivered the next day.

In many cases, these companies are also receiving soft-cost savings by being able to better manage their brands. Before working with us, most of our clients’ international dealers were ordering their own printing, and the result was inconsistent print quality, inclusion of outdated content, and overall inefficiencies in process. By moving to a centralized brand portal and routing the jobs to international partners with consistent production standards, these large international brands are able to regain brand control.

Our clients also gain predictability for their international printing because our partners know the “rules of the road” around the world. This includes the unwritten rules of a region that would take a U.S. printer years to learn. For instance, if a partner needs to ship our job into Turkey, I’ve learned that you can’t do it in big boxes that weigh over 50 pounds because these trigger inspections and slow delivery. If we want to get it there without delay, we have to break the project down into smaller, lighter-weight boxes.

We are often asked how we make money on these deals. The answer is that we don’t — at least not on the jobs themselves. Only 5 percent of our revenue comes from jobs printed internationally. We make our money on the rest of the work we do for these clients. Here’s the thing: Before I take on a client’s international printing, they must commit to giving us all of their North American printing as well. I prefer a minimum of $250,000 annually. Today, 25 percent of our revenue comes from clients who participate in our international printing program, even though the bulk of that revenue actually comes from their North American work.

International printing capabilities also give us the opportunity to bring on clients we’d never otherwise have. A recent bid proposal came down to us and one other printer, but we had the international printing component figured out. We won the bid, and this client is now our second largest.

Just in the last few weeks, I’ve had two very big companies contact me about setting up international printing portals. If I land both of these deals, our overall revenue will increase by 10 percent within 12 months.

The Next Game-Changer

International printing was a game-changer for us, no doubt. Now we’re looking for the next one. Currently, I’m spending a great deal of time on a new product that will have a huge impact on our direct mail business.

What I can tell you is that it’s a truly multichannel solution that will allow me to route the same client ads to print, direct mail, and digitally, to Facebook and Google. That is, I can capture everyone who lands on a client’s website, send them direct mail, and continue that conversation with brand-consistent, integrated digital ads delivered across the web. I’m excited, not just because it’s a great solution, but because I know that I have 50-60 hours of work in front of me before I’m ready to roll it out. This means that most of my competitors won’t do it.

What’s after that? Who knows. I’ve always believed that, in life, you figure out what you do well, then do it. If you work harder (and smarter) than everyone else, you can do great things. I’m going to continue living and running my business this way, trying to get every drop out of myself that I can.

Al Kennickell is president and owner at The Kennickell Printing Group in Savannah, GA. If you come in on a Saturday, you’ll find Al sitting at his desk with a blank yellow pad, letting his mind wander. These brainstorms are what Al considers his greatest competitive advantage. You never know what idea will become his next game-changer. Connect via kennickell@leadingprint.org.

Other recent articles

The Vanishing

Weighing In

We’re OK

The Guide

By The Numbers