By Doug Rawson

[stag_dropcap font_size=”100px” style=”normal”]W[/stag_dropcap]hat most people could never imagine about our printing company is how different things looked ten years ago. We’ve gone through a total overhaul. And if you wonder whether it’s scary to totally restructure a functioning business, and do it in ways that take a lot of the control out of the hands of the CEO? Yes, it is.But I can tell you the choice is a lot easier when it’s the only option you have. Things were grim for us back then. We were struggling with low morale, stagnating sales, and thin margins. We were making the same quality errors again and again. No matter what we tried in sales and marketing, we couldn’t grow revenue. I was working 14-hour days, with a line of people at my office door looking for direction. Everyone was exhausted.

Fast-forward to today, and we have a healthy bottom line — we’ve doubled our sales revenue in the last seven years. And our employees are happy — last year, we were named one of the best workplaces in the Americas. What made the difference for us? A serendipitous and very timely introduction to LEAN manufacturing practices. It dramatically changed the trajectory of our company.

Why LEAN?

I first heard of LEAN at the 2011 PIA Continuous Improvement Conference where Capt. Michael Abrashoff was the keynote speaker. That’s right — Captain. Graduate of the U.S. Naval Academy, former Commander of the destroyer USS Benfold. What could he tell us about LEAN principles? As it turned out, a lot. This naval officer turned successful businessman authored a book called “It’s Your Ship: Management Techniques for the Best Damned Ship in the Navy.” In the book and his talk, Abrashoff describes how he ran his ship as he would have run a business. He shares the LEAN principles he used successfully — like fostering a shared sense of purpose and seeking the input of everyone involved.

Now, I’m a sales guy. That’s how I got my start in this business. I had no training on how to build a company or how to be a CEO, and I wasn’t in a position to take time off to learn. What Capt. Abrashoff provided was an effective business structure and a practical path towards achieving that structure. It made a lot of sense to me and seemed very achievable. I was won over.

The basic premise of LEAN business practices is straightforward: Identify and eliminate waste wherever you find it. It can be the waste of time, waste of materials, even waste of workers’ energy. It all lowers productivity. Secondly — and perhaps most importantly — begin implementing waste-reduction changes at the most fundamental levels of the company. In our case, that meant starting with the pressroom. Too often, management tells people how to do their work. But thanks to their natural disconnect from the actual work, this means management is making a lot of assumptions, many of which are probably wrong. But those folks on the floor? They know every detail of our processes and the resulting outcomes. LEAN says, bring them to the table to identify needed improvements and potential efficiencies throughout the entire operation.

Fighting Fires

I started this company 30 years ago. Based in Los Angeles, Superior Lithographics produces litho labels and top sheets for corrugated box converters and folding cartons. Much of our product is used for food packaging. For the first 23 years, we functioned as a traditional top-down printing company: The executives set goals; middle management implemented directives; and the production teams produced the work.

Our company grew over those years, but the growth wasn’t keeping pace with our objectives or costs. The shrink caused by inflation and the increased costs of materials were eating into our profits. We tried everything we could think of to correct this — hiring new supervisors, increasing marketing efforts, bringing on more salespeople. Nothing made a discernible difference. We even devised a new commission plan to help generate more sales. But more sales don’t equal greater productivity. In fact, as our sales increased and we brought in more jobs, our shortcomings were exposed. We had poor management practices, and our processes and procedures weren’t scalable. We became firefighters, constantly putting out blazes and never implementing lasting fixes to the underlying problems.

Fortunately, this was about the time I heard Capt. Abrashoff’s talk. The LEAN principles are so simple. As I learned more, I thought, “I can do that!” I returned from that conference and told everyone, “I’ve seen our future, and it is LEAN.”

Try Every Suggestion

The most effective LEAN step we’ve taken, the one that has yielded the most impactful results, was our first. I met with each member of our team, all 70 of them at that time, and asked, “If you owned this company, what would you do to improve it?” These conversations exposed a lot of what was wrong but also gave us concrete ideas for how to address these problems.

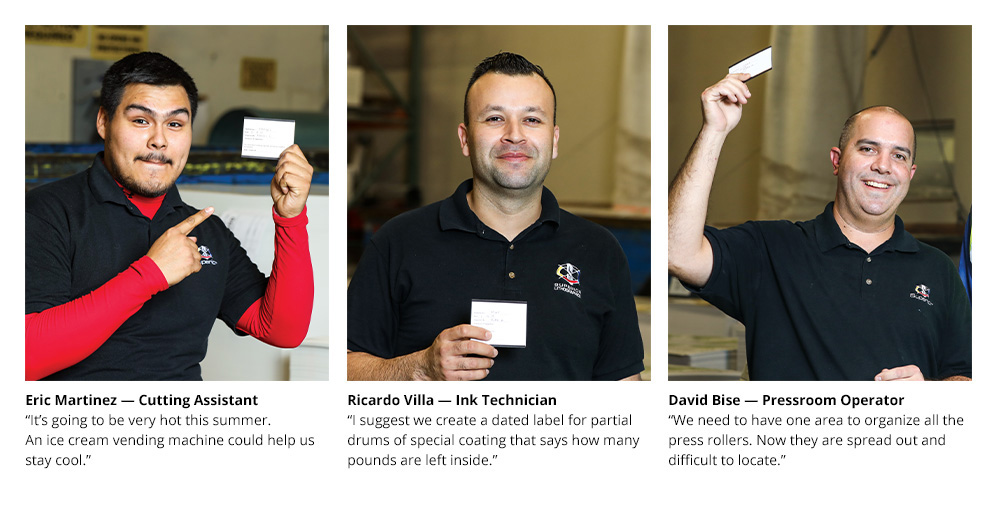

After the initial conversations, we developed a system that allowed us to continue collecting employee input on an ongoing basis. You could call it an electronic suggestion box. To this day, we encourage all of our employees to contribute ideas they think will improve conditions at the company — no matter how simple, complicated, cheap, or expensive those ideas might be. Think big, we say, because we are committed to making investments in the company.

Most importantly, we started this with a commitment to which we have stayed true: We will at least try every suggestion (unless it poses a safety concern, is unaffordable, or conflicts with our stated values). These aren’t just words; it’s a pledge we have followed since day one.

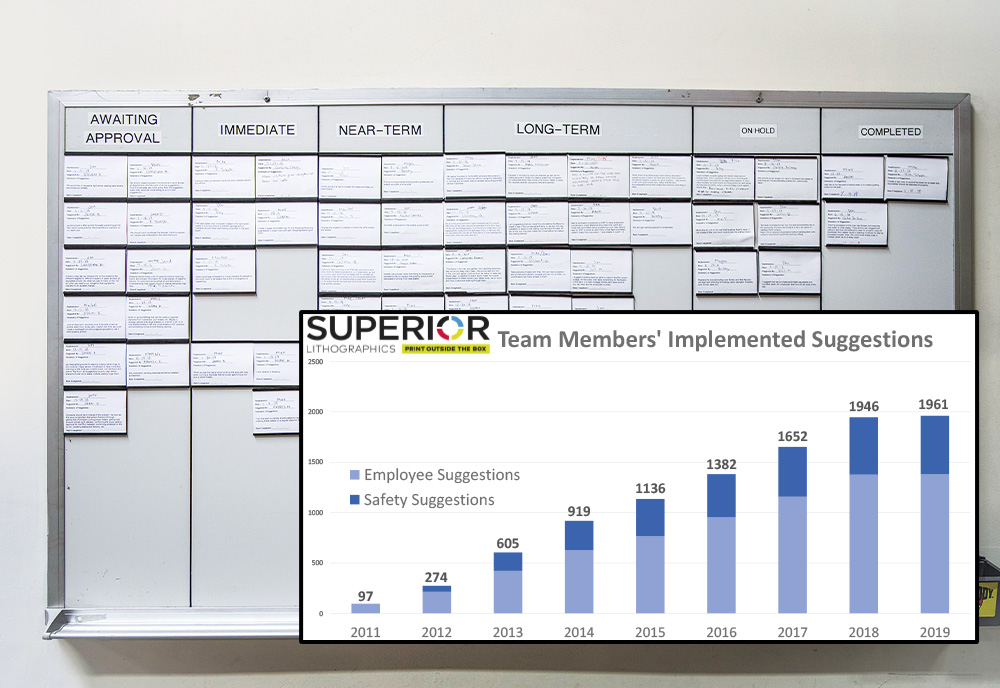

At the onset, we set up a whiteboard that everyone in the company can see. There we list every idea, the person who proposed it, and the date we received it. The ideas are mounted with magnets, and we move each through our implementation stages: “awaiting approval,” “immediate,” “long-term,” and “completed.” The board provides accountability. It shows everyone that we mean what we say; that we will follow through; and, perhaps most importantly, that their ideas matter.

It was challenging at first to get staff to participate. It took courage for people to propose their ideas to the entire company. But once a few courageous individuals took the leap, many followed.

Initially, the suggestions addressed safety, comfort, and process. Some of them were so simple, I couldn’t believe it — things like installing fans for hot weather or cushioned floor mats in spaces where staff stand for long hours. But it was obvious that the resulting changes were good for our employees, and thus good for our company and, most importantly, our customers. Happy employees are motivated and productive employees. We didn’t need to conduct studies to see it. We saw the change in the morale around the plant. One employee, someone who is also a veteran, asked if we could hang an American flag. We did (and also hung the California state flag). He was incredibly grateful and still reminds people that this was his suggestion. With most of the proposed ideas, I asked myself why we hadn’t been doing things this way all along.

As we continued, the suggestions moved beyond the basics and started addressing areas like quality control and even sales. Someone suggested changing the flooring in production areas because the white floors showed dirt quickly and didn’t look good when new customers toured the plant. I loved this suggestion because it showed that the staff was becoming invested in the organization, taking pride in how we present ourselves and being aware of how that impacts sales. They were showing a transition from employees to team members.

Not everyone pitched in enthusiastically at first, but most came around. In one case, a skeptical pressman eventually contributed a suggestion: to store ink closer to the presses. As it was, the pressmen needed to walk through two rooms to access the ink supplies. We received his idea at 11:00 a.m. and added it to the whiteboard. Soon after, someone headed to the local Home Depot to purchase shelving and set it up only a few steps away from the presses. They finished by 3:00 p.m. We had received his suggestion, acted on it, and solved the problem in four hours. Needless to say, this one reluctant participant became an active believer in our initiative.

At the End of the Day

While many of the initial ideas represented low-hanging fruit, they opened our eyes to the fact that we also needed to make bigger changes. It was no longer good enough to do things as we’d always done them.

To the contrary, we discovered that a lot of the new ideas were much better than our old practices. Whether it was the positioning of equipment, like mounting a hook to get a charging cable off the floor or relocating a cutter closer to the people who use it most often, these ideas were coming mostly from the production staff, not from management.

“While many of the initial ideas represented low-hanging fruit, they opened our eyes to the fact that we also needed to make bigger changes. It was no longer good enough to do things as we’d always done them.”

This caused a lot of the resistance from middle management. These individuals were concerned about how all the changes would affect them. It was the old, “If I try this system, it’s going to put me out of a job.”

Of course that was not the intention behind the initiative, but it did create a sea change. Ultimately, most of our middle management chose, of their own volition, to leave the company. In the end, this was a good thing. I realized that these legacy employees were not going to take us to the next level. Most had too much invested in keeping things the way they were — though those ways weren’t good for the growth of the company or of our team members.

These departures caused a disruption, but it was short-lived. We sought out and hired new managers who fully support the LEAN system and processes.

Nurturing Talent

Through the early steps of this initiative, we discovered another instance of waste: under-developed talent. We realized how little mentorship and training we were providing to our staff. For example, the press operators had never been trained on how to set the press rollers, a regular task. A supervisor had always done it. This was like having a pilot who knew how to fly a plane but had to call in his supervisor to land it. It was that inefficient. We contacted the necessary vendors, who came in and ran a 4-hour workshop — two hours in the classroom and two on the floor. Now, every member of our press team is trained and empowered to perform this function.

We also send people outside of the company for training. If someone finds a course they want to take or a conference they want to attend, we encourage them and pay their expenses. We recently sent a pressman to the PIA Color Conference. When he returned, we had him share with the others what he had learned and the contacts he’d made. Next year, someone else gets to go. These costs are an investment in our workforce, which makes them good for the company and our customers.

1,900 and counting

We’ve been at this for seven years now — and recently completed the implementation of our 1,961st staff suggestion. Yes, that’s right: Over one thousand, nine hundred ideas brought to fruition. Every change we’ve made has created an improvement over what we had been doing.

And the business results are impressive. Since December of 2017, we have increased our operating schedule to 24/7. This has reduced our printing press hourly costs by 35 percent. In 2011, we had $14 million in sales. In 2018, we more than doubled that at $30 million.

Like everything we’ve done, everyone is a part of this, so everyone benefits. We distribute 35 percent of our profits to the workers in the form of bonuses. In 2018, Printing Industries of America awarded our company with a “Best of the Best Workplace in the Americas” distinction — an honor we are very proud of.

“Like everything we’ve done, everyone is a part of this, so everyone benefits. We distribute 35 percent of our profits to the workers.”

This is a far cry from our pre-LEAN days. Fortunately for everyone, we took this leap of faith. As a result, our company is thriving, and the people doing the work are better off. They’re better trained, happier, more fulfilled. And if our story serves as an example of a profitable 21st century printing company, I’d like to think that sharing it will help lift others in our industry, too.

To me, those are the results that really matter.

Doug Rawson is the president and CEO of Superior Lithographics, a company he started to create high-quality labels for corrugated boxes to serve a new retail warehouse phenomenon called Price Club, which we now know as Costco. They continue to produce litho labels for corrugated box converters and folding cartons for the food industry. Connect via rawson@leadingprint.org.

Other recent articles

The Vanishing

Weighing In

We’re OK

The Guide

By The Numbers