Daily Printing’s focus on profitability yields big results.

By Tom Moe

I once heard a story that profoundly impacted how I think about managing costs, whether for a printing company like ours or any other type of business. American Airlines was looking for ways to cut costs in the 1980s, and the top executive posed this question: “How much money could we save if we removed one olive from every dinner salad served to passengers?” The answer was about $40,000 per year.

You might wonder how one olive could make such a difference, but it’s not just a single olive. It’s one olive per salad, multiplied by all of the salads served by American Airlines in the course of an entire year.

Although this story has been around for over 30 years, the lesson continues to influence many CEOs today, including me. The lesson is not to ignore the little things. Over time, little efficiencies accumulate into big efficiencies, and small cost savings multiply into large ones.

This “olive” lesson has been particularly impactful for us here at Daily Printing. We are a $12-$15 million commercial printer in Plymouth, Minnesota, that offers digital and offset printing, marketing and graphic design, mailing services, and warehousing and fulfillment. But unlike most companies, we don’t have a single owner. We have 70 of them. Daily Printing is 100-percent employee owned. As the president and CEO, I have a responsibility to make the business profitable for them.

From this perspective, growing our sales while breaking even wasn’t good enough. We had to change our strategy to achieve true profitability. To do this, we developed a three-pronged approach:

- Cut loose unprofitable customers.

- Create a meaningful differentiation strategy.

- Reduce costs through a ruthless elimination of inefficiency (or, olives).

From Breakeven to Profitable

We have 800 competitors in our “local” marketplace. When I look out the window from my office, a competitor sits 100 feet away. Halfway down my block is another one. Over my right shoulder is another. Surrounded by so much competition, we are not going to win this battle on price. Nor do we want to. As a profit-driven company, we want to be driven by margins and value.

So how have we gone from breakeven to profitable? It started by charging our customers what our services are worth. Daily Printing has always been customer-centric, and we could not continue to offer the best service, the best production quality, and an outstanding range of high-end services at cut-rate prices. We had to increase our margins.

But first, we had to know which of our customers were profitable and which weren’t. When we took a hard look at our costs — a really honest look — we were surprised. We weren’t making a profit with some of our customers, even our largest ones. Maybe their turnaround times didn’t make sense. Maybe there wasn’t enough margin. Whatever the reason, we were barely breaking even, and in some cases, were losing money. It was time to have some difficult conversations. We had to help our unprofitable customers understand that we are a business just like they are. If we don’t make money, we don’t stay in business. We had to raise our prices.

These conversations weren’t easy, but they were necessary. And three things resulted:

- A portion of our customers took the leap of faith with us.

- A portion chose to take their business elsewhere.

- A portion left, and then after working with other printers, realized our value and came back.

During this process, we had to say goodbye to some large accounts and one of our salespeople. However, Daily Printing is now in a much better financial position. Although our revenues overall are down, we’ve gone from breakeven to profitable.

Will we rebuild our revenues to where they were? That is the goal, but if we don’t, we are okay with that. My responsibility is to make money for the owners of this company. It’s more important to be a $15 million printer with 4- to 5-percent profitability than a $25 million printer breaking even.

My responsibility is to make money for the owners of this company. It’s more important to be a $15 million printer with 4- to 5-percent profitability than a $25 million printer breaking even.

Moving Beyond Price

Becoming profitable has required us to do more than change our prices. We have had to change the way our customers think about us. They have to see us as a premium partner worth a premium price.

One of the ways we’ve done this is by starting a robust content marketing program. This is an opportunity for us to demonstrate that we understand the challenges our customers face and that we’re committed to providing them with resources to help solve those challenges — or simply, to help them be better at what they do. Our program includes a magazine, called Connect Daily, and live educational programming. Connect Daily is about print, but in the bigger picture, it’s a magazine focused on marketing — intended to help our customers market themselves more effectively. It’s written by the professional writers at Conduit, a publisher of niche magazines to the trade. We publish seven times per year, in print and digitally. Once each year, we have a special issue focused exclusively on print.

We supplement the magazine with an annual, half-day educational event. Based on the feedback we receive from readers about what resonates most with them in the magazine throughout the preceding year, we identify topics and develop a theme for each event. The programming starts with lunch, includes a keynote and breakout sessions, and ends with happy hour. (One of our recent keynote speakers was Dr. Colby Jubenville, co-author of “Zebras and Cheetahs: Look Different and Stay Agile to Survive the Business Jungle” and “Me: How to Sell Who You Are, What You Do, and Why You Matter to the World.”) For the breakout sessions, we invite supporting speakers, such as local vendors, or customers who are implementing ideas covered in the keynote. One of my favorite sessions was built off of a magazine article about micro-branding. This was right around the time craft brewing was starting to take off, so in the live event we featured several local micro-breweries and how they’re effectively competing against their larger competitors.

Thompson Reuters, well-known legal publisher, spoke at our first educational event about how they were using big data to drive mail programs. They were producing a personalized direct mail piece for attorneys around the country and varying the text and photos based on each attorney’s type of practice and the continuing education credits they needed to maintain their license. Not only did educating our clients about personalized, data-driven mailings help them achieve better results, but it helped us drive more print revenues when they came to us for the related services.

After four years of offering content marketing, I can say without a doubt that it has changed how our customers see us. Not only has it allowed us to compete without having to be the lowest price, but it has helped us to retain customers, which of course has a direct impact on profitability. According to Bain & Company, a 5-percent increase in customer retention can increase a company’s profitability by 75 percent. According to Emmet Murphy & Mark Murphy (“Leading on the Edge of Chaos”), a 2-percent increase in customer retention has the same effect as decreasing costs by 10 percent.

[the_ad_placement id=”leadboard-ads”]You Can’t Control Costs in a Silo

Improving profitability has required improving our cost-efficiencies. We have analyzed every aspect of our business, including administration and production, to eliminate waste and become more efficient. We have had to ask hard questions and bring together cross-functional teams in order to uncover these opportunities.

This has demanded a real cultural change. As in many companies, decisions at Daily Printing were made in silos historically. Production made production decisions. Sales made sales decisions. Finance made financial decisions. There was some cross-team discussion, but there wasn’t a strategic emphasis on cross-functional collaboration.

Our first effort at this type of collaboration was in early 2018 when we decided to look at the efficiency of our production workflow. Our presses were still producing great work, and we had an excellent relationship with our existing vendor, who was handling everything from production equipment to software. But we wanted to know: Was there something we were missing? Was there a different solution out there that would make us more efficient? It was worth asking the questions.

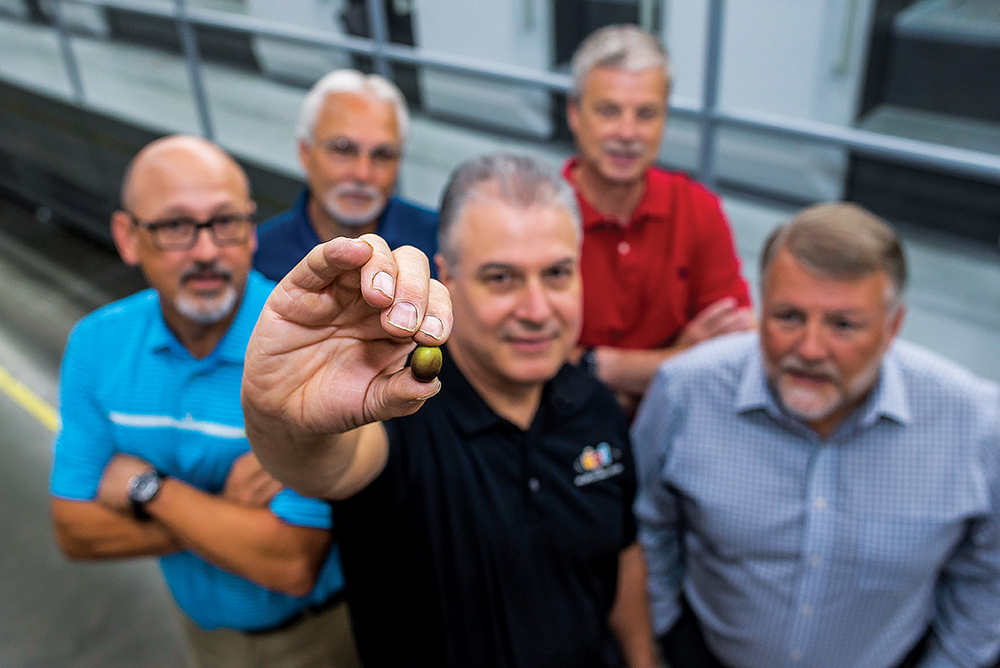

To get the answers, I assembled a team that included five employees who, together, represented the functional areas of our business. We had a pressman, a salesman, a production manager, the vice president of production, and me. Each of us brought a critical perspective to help the team identify and solve inefficiencies — and to consider new opportunities. Even though this process revolved around production, for example, I wanted a salesman on the team to help us identify hurdles to new sales and understand whether new equipment could open doors to opportunities.

When we first started out, the biggest challenge was bandwidth. This process took five of our top people away from their primary jobs for hours, sometimes days, at a time. We traveled around the country, visiting client sites and talking to press operators and, sometimes, end clients. This required huge sacrifices from the team, but it was important that all of us be committed to the process.

The other challenge was helping everyone on the team understand that they were on a level playing field. Everyone put in the same amount of work, and everyone had the same vote. No one person, whether that was the CEO or the salesperson, could exert more influence than another. This took some diplomacy to work out, but as a management team, we learned a lot. The salesperson would say, “We’ve been locked out of jobs because of X,” or the pressman would comment, “This feature on a press would help us churn out more work.”

To get the answers, I assembled a team that included five employees who, together, represented the functional areas of our business. We had a pressman, a salesman, a production manager, the vice president of production, and me. Each of us brought a critical perspective to help the team identify and solve inefficiencies — and to consider new opportunities. Even though this process revolved around production, for example, I wanted a salesman on the team to help us identify hurdles to new sales and understand whether new equipment could open doors to opportunities.

At the end of the process, we came to a very unexpected conclusion. We went into this happy with our current vendor and with no complaints about their equipment, quality, or service. But hearing different perspectives and thus adding new criteria to our search led us in a different direction. We chose a new vendor. And we replaced three older pieces of equipment with one faster, more productive press. Instead of running two 40-inch and one 29-inch presses for one shift a day, five days a week, we would now run our new press 24 hours a day. Between the efficiency of the new equipment and lower maintenance costs, we are now saving at least $200,000 per year. And we’re getting as much productivity out of that one piece of equipment as we were with the other three combined.

Earlier this year, we used the same process to evaluate the digital side of our business. With lessons learned from the first cross-functional team (such as evaluating equipment at once, at a national trade show, instead of over multiple trips), we came to a decision in 60 days. Our new digital press was installed in July 2019.

We will continue to use cross-functional teams at Daily Printing. The approach has allowed us to look at issues from multiple angles, incorporating the perspectives of multiple departments and disciplines. This has enabled us to uncover not just cost efficiencies, but better production practices and new sales opportunities.

Focusing on Variable Costs

While it’s tempting to focus on the big-ticket items, big cost savings come down to the small things, too. It’s not just how fast a press runs or how much throughput you can get in the bindery. Like olives in salads, it’s finding and addressing the little pockets of inefficiency that, when addressed, add up to huge savings. We have been able to find cost savings of $7,000 here, $15,000 there, and $60,000 way over there. When we add them all up, we are looking at saving upwards of $100,000 just from small process improvements.

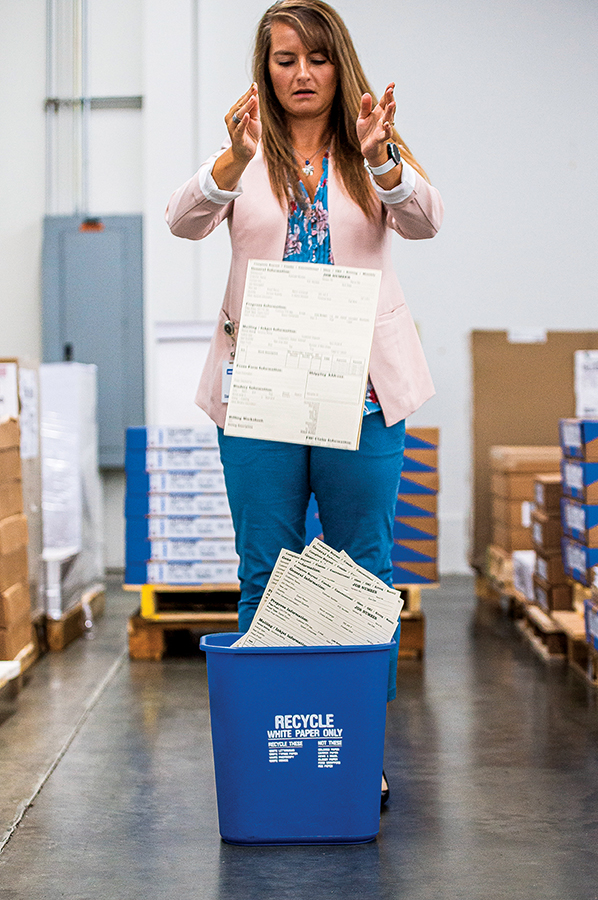

[the_ad id=’214′]Take, for example, our job tickets. Like most printers, our runs are getting shorter, but it doesn’t cost any less to process a job ticket for a short run than for a long one. We look at it this way: Every human touch inside our company costs us $25. If it costs us $75 to process a job ticket, we can’t afford to take on digital orders for just $50 each. We will lose money every time, and the more of those orders we take, the more money we lose.

The solution isn’t to turn away these small jobs, but to manage them smarter. So we tweaked our client web portal so it can handle short-run, ad hoc jobs. Now clients can upload PDFs and put them in the queue, no job tickets involved. Instead of billing for each job individually, we bill each client once at the end of the month. One of our customers does 100 of these jobs per year, so eliminating job tickets saves us $7,500 per year from that account alone. If our profitability is at nearly 4 percent, that’s the equivalent of adding more than $125,000 in business per year. One little change — one olive — creates the impact of adding a major account.

The same approach applies to another very simple administrative component of our business: writing checks. Every time we write a check to our vendors, it costs us $70 in soft and hard costs. We’re striving to eliminate as many checks as possible by transitioning to other payment methods. This includes creative solutions like paying all of the expenses to a vendor with a single check at the end of the month or by using a purchasing card, similar to a credit card, which enables us to pay a balance in full each month.

Applying this concept has been successful in other areas as well. In operations, we asked, “How much can we save on our electric bill if we replace traditional light bulbs with LEDs?” Turns out, $15,000 per year. In shipping, we challenged our shipping department to reduce the use of outside courier dock trucks. They were able to go 15 months without using a dock truck, saving us $60,000. When you add up all of our accumulated savings, the number is huge.

We’ve been on this journey for four years. At the end of the day, the question is, “Has it worked? Is Daily Printing more successful than it was four years ago?” The answer to that is “absolutely.” By the end of the first three months of the fiscal year, we had tripled our net profitability. And our client base is expanding. In the last fiscal year, we opened 46 new accounts. This calendar year, we opened 39 accounts in the first four months alone, and they are large accounts with growth potential.

Many CEOs believe, “To be profitable, we just have to sell more.” That is not a philosophy I subscribe to. No matter what your sales are, you can be profitable. Then, as your sales grow, your profitability grows exponentially.

This is why I don’t focus on revenue goals alone. I focus on profitability goals. You can be a $25 million printer and not make any money. Or you can be a $10 million printer with 5-percent profitability. Five percent of $10 million is half a million dollars. In the choice between breakeven and half a million dollars, I’ll take the $500,000.

Tom Moe is president and CEO at Daily Printing. He has been told that he needs to take “print” out of the company name, or the company will be pigeonholed and die on the vine. His response? “My philosophy is, that’s a great strategy if you’re a crappy printer.” Connect via moe@leadingprint.org.

Other recent articles

The Vanishing

Weighing In

We’re OK

The Guide

By The Numbers